MOULD CLEANING SERVICES

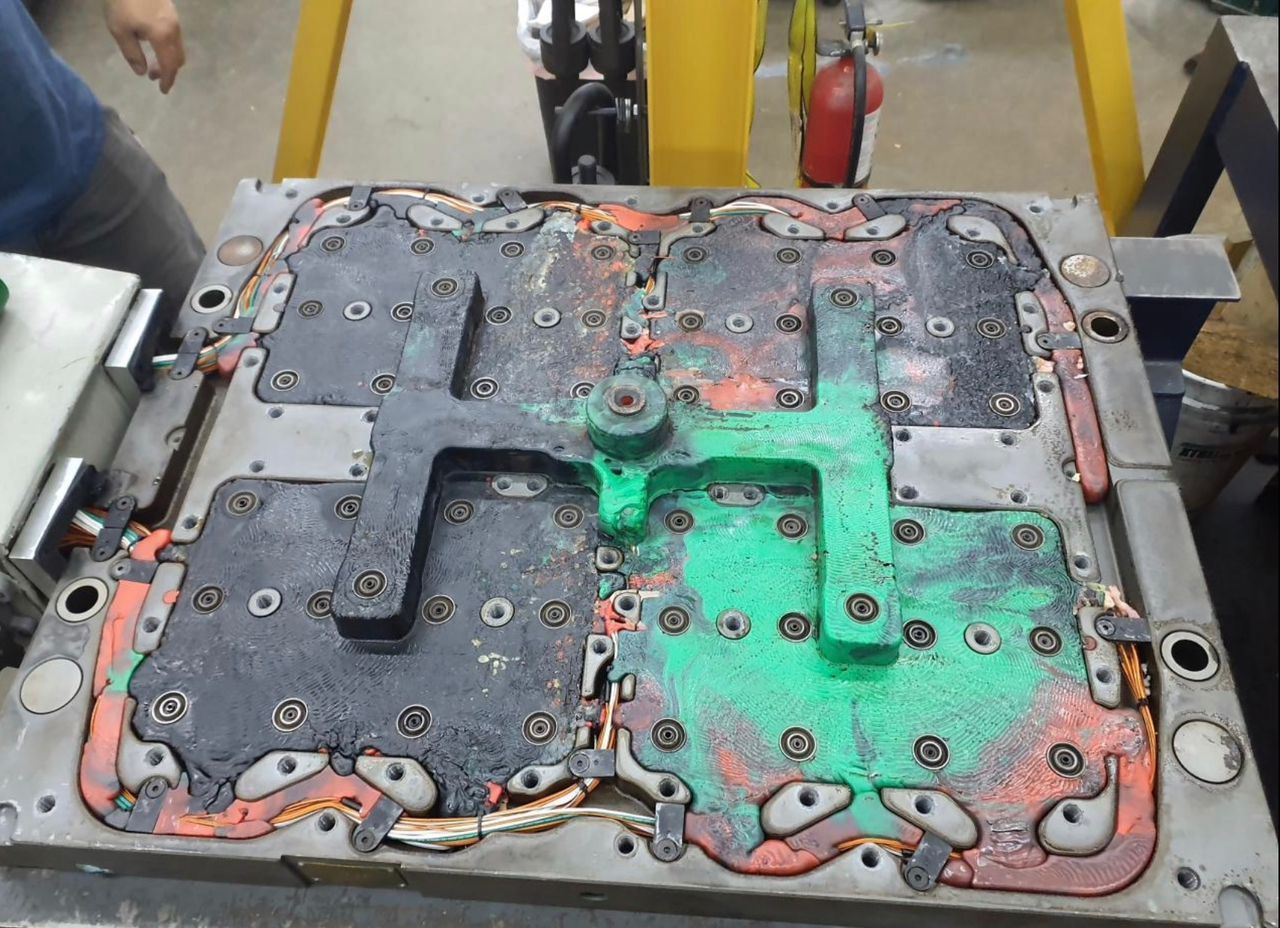

Troubling over your flooded hot runner tooling? FRET NOT....

We operate the largest state of the art fluid clean machinery in Malaysia providing the plastic processor safe, non-abrasive, quick polymer removal solutions for the injection molding and other plastic processing industries.

The Cleaning Process

The main part of the system is an insulated reactor containing sand particles. The sand is brought to a bubbling, fluidized state by Injecting air from the bottom. The reactor is directly heated using a flame shield at the bed surface in order to achieve the extreme temperature. The fluidized sand ensures that the parts are subjected to an even temperature profile to avoid distortion of any kind.

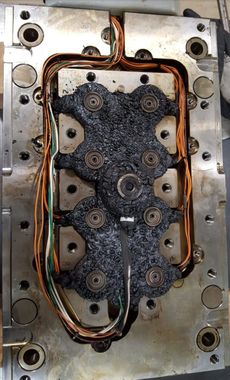

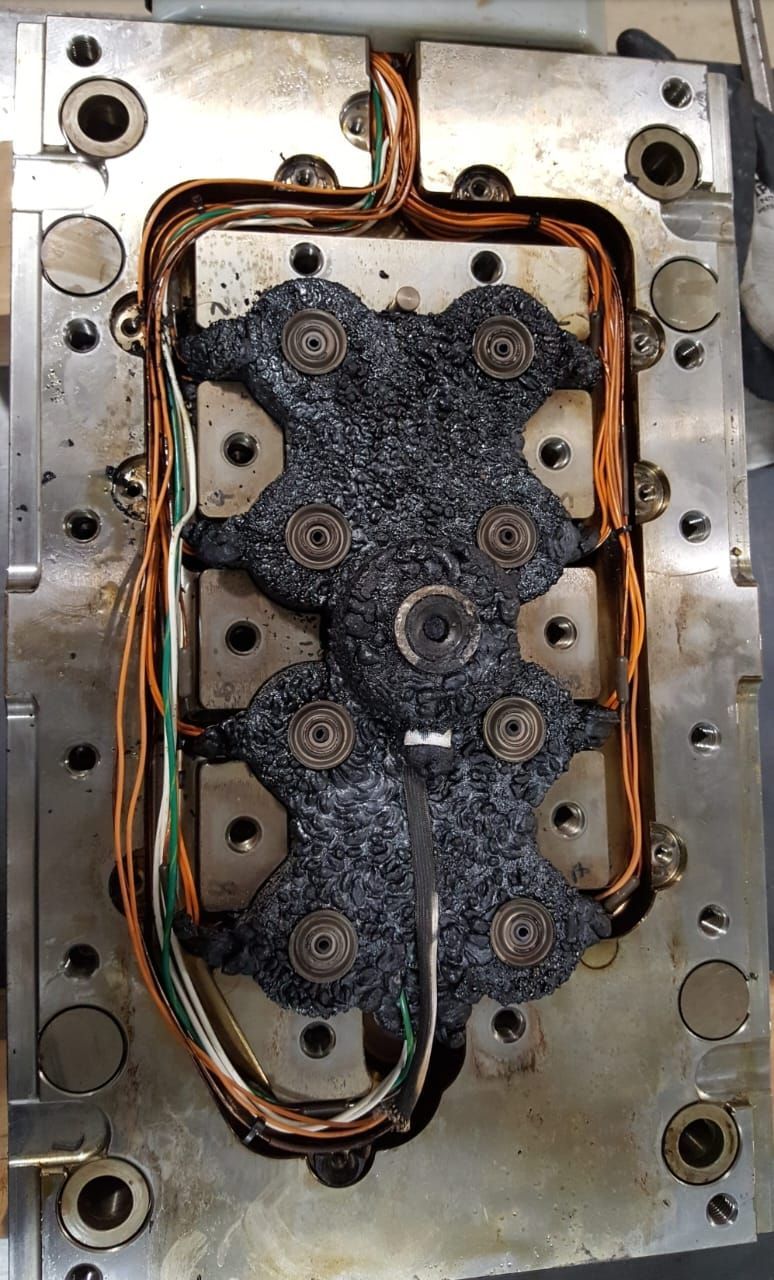

The old plastic is thermally degraded within the sand bed and toxic gases are then oxidized at the bed surface using the flame shield. Inorganic particles are abraded by the sand particles and blown out of the sand bed and captured in a filter system.The inner runner is then being dry ice blasted to ensure no sands or residues being left inside.

Further inspection on heating elements and thermo-couples will be conducted and most parts are stocked in-house. Less downtime, greater efficiency!